SuperPeaker Technology

A Revolutionary Combined Cycle Power Plant

The Synergic Superpeaker is engineered to set a new benchmark in combined cycle power generation. Leveraging proprietary systems and cutting-edge integration of aero-derivative gas turbines, once-through steam generators (OTSGs), and impulse-type steam turbines, the Superpeaker achieves unmatched performance, flexibility, and cost efficiency.

Unlike traditional combined cycle plants, the Superpeaker incorporates air cooling and aero-derivative gas turbines — an unconventional yet highly effective combination. This innovation enables rapid startup, higher efficiency, and lower maintenance costs, setting the Superpeaker apart from any other plant in its class.

Advanced Air Inlet System

The Superpeaker's air inlet system is meticulously designed to maximize gas turbine performance while minimizing degradation and maintenance costs.

Filtration and Chilling System

Optimized Inlet Ducting

Aero-derivative Gas Turbines

The Superpeaker employs aero-derivative gas turbines renowned for their exceptional flexibility, rapid startup capability, and high reliability. Compared to industrial turbines, these turbines offer quicker responsiveness, making them ideal for dynamic load management.

Proprietary Gas Turbine Exhaust

The Superpeaker features a proprietary high-temperature refractory exhaust design that merges directly with the OTSG base, delivering several key advantages:

Once Through Steam Generators

The Superpeaker integrates state-of-the-art Once-Through Steam Generators (OTSGs) from Innovative Steam Technologies (IST). OTSGs are a key factor behind the Superpeaker's fast starts and high efficiency.

Key Benefits:

Impulse Type Steam Turbine

The Superpeaker's steam turbine is a two-pressure impulse-type design optimized for flexibility and reliability.

Impulse Design Advantages:

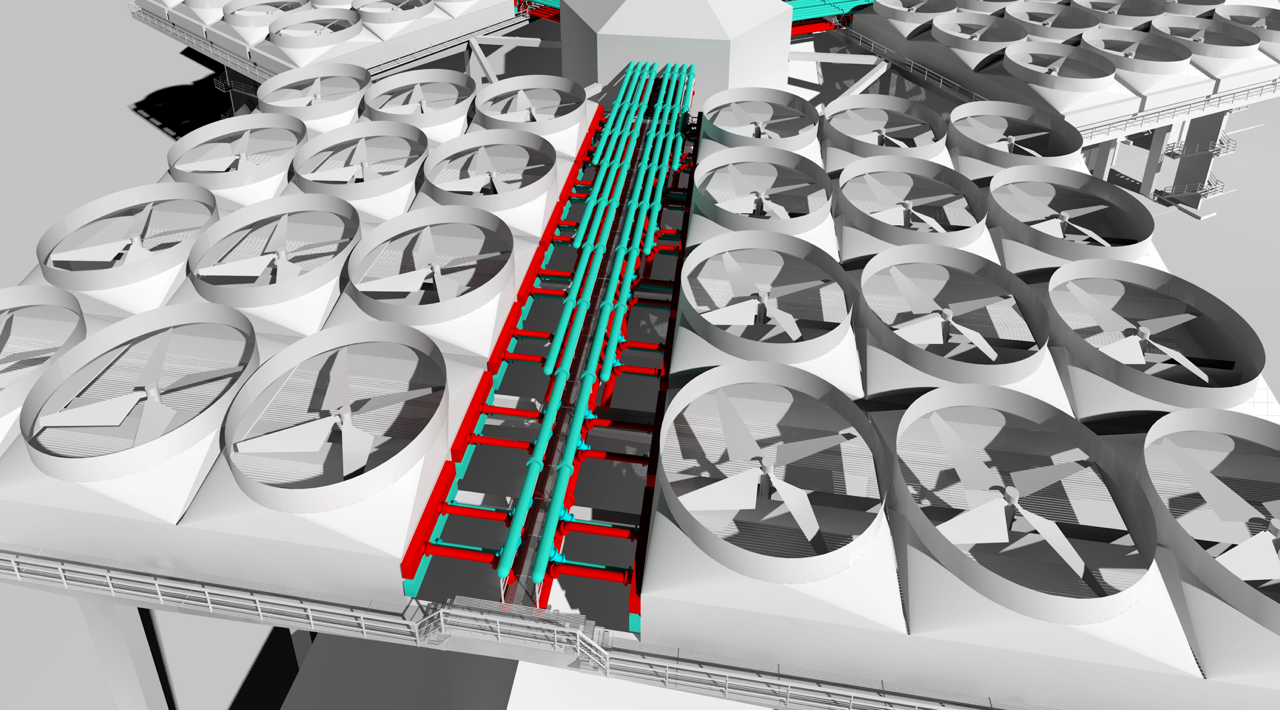

Synergic DCC

The proprietary Synergic DCC distinguishes the Superpeaker plant by dramatically enhancing steam cycle responsiveness and flexibility, matching the performance characteristics of the aero-derivative gas turbines and OTSG.

Highlights of the Synergic DCC include:

SynVane Coolers

SynVane Coolers represent the next generation in turbine blade cooling technology. These innovative cooling systems utilize advanced aerodynamic principles and precision-engineered cooling channels to maintain optimal blade temperatures.

The unique design allows for higher operating temperatures while extending component life, resulting in improved efficiency and reduced maintenance requirements.

Tri-form Building

The Tri-form Building system revolutionizes power plant construction with its innovative modular design approach. This advanced construction methodology combines three key elements: rapid assembly, optimal space utilization, and enhanced structural integrity.

By utilizing pre-engineered components and smart integration techniques, the Tri-form system significantly reduces construction time while ensuring superior quality and reliability in power plant infrastructure.

The Future of Energy Technology

Tomorrow's power generation solutions will seamlessly integrate renewable and thermal technologies, providing clean, reliable, and flexible energy for a sustainable future.